Introduction

In plant audits and project reviews, one mistake shows up again and again: vertical pumps are selected purely on flow and head, without considering sump geometry, fluid behavior, duty cycle, or maintenance access. On paper, the pump looks right. On site, it cavitates, vibrates, or becomes a maintenance headache within months. Vertical pumps are not interchangeable variants of the same machine; each type solves a very specific industrial problem.

This guide is written from the perspective of real installations across water treatment, HVAC, mining, chemicals, and process industries. The goal is simple: help engineers and decision-makers avoid misselection, downtime, and premature failures by choosing the right vertical pump for the right operating reality.

Understanding Vertical Pump Selection Beyond Flow & Head

Vertical pump selection should start with installation constraints, not just hydraulic numbers. Sump depth, fluid temperature, solids content, NPSH availability, and maintenance philosophy directly influence which design will work reliably.

Ignoring these factors often leads to common failures: bearing damage due to dry running, seal failures from poor lubrication, or excessive vibration caused by incorrect column length. A vertical pump that matches the system mechanically will almost always outperform a higher-efficiency pump that is poorly matched to site conditions.

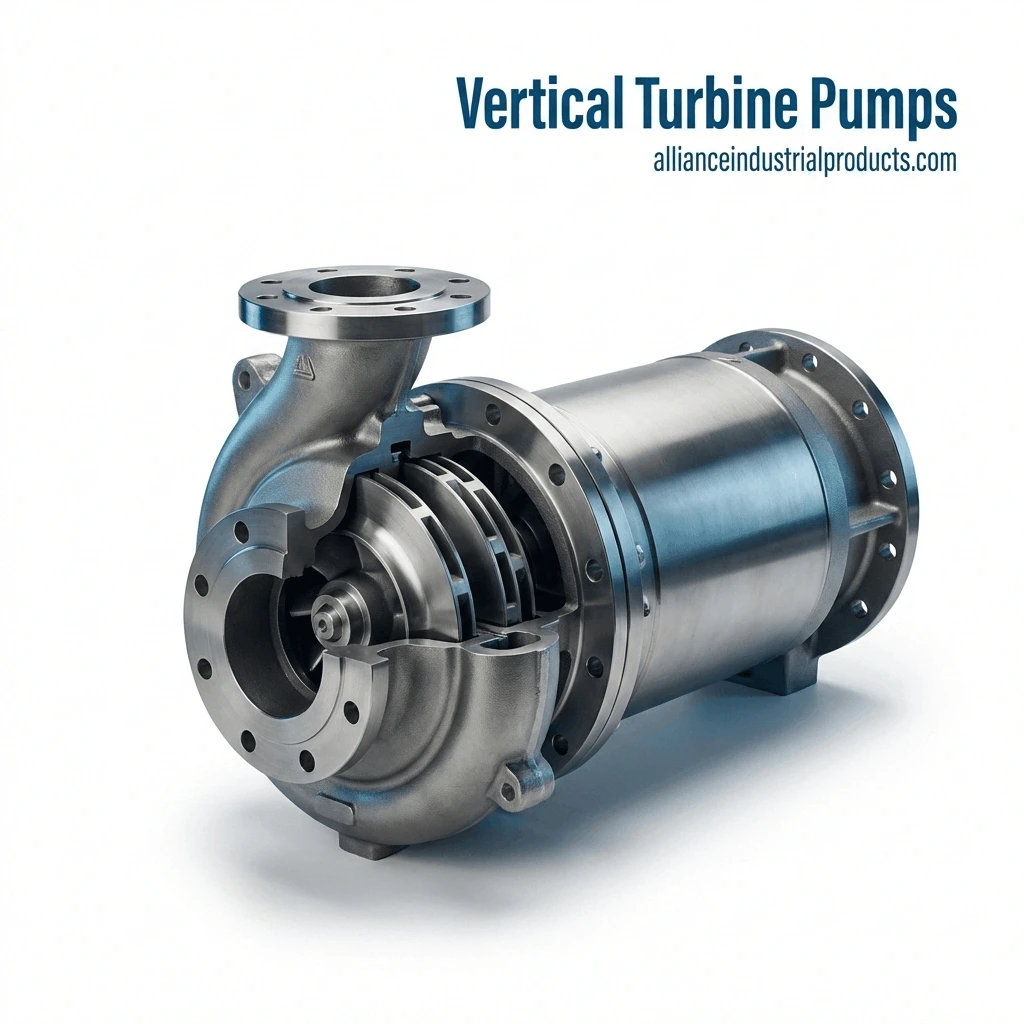

Vertical Turbine Pumps – Best for Deep Sumps and High Reliability

Vertical turbine pumps are commonly specified in water intake, fire protection, and irrigation projects, but problems arise when bowl design and submergence are overlooked. Inadequate submergence leads to vortex formation, air ingestion, and fluctuating discharge pressure.

These pumps perform best where suction conditions are stable and continuous operation is expected. They are not ideal for frequent start-stop applications unless thrust bearing and motor sizing are carefully reviewed. Proper column alignment and material selection are critical for long service life.

Vertical Multistage Pumps – Compact Pressure Boosting, Not Process Workhorses

Vertical multistage pumps are often chosen for their small footprint and high pressure capability. In real-world installations, they excel in clean water pressure boosting, cooling circuits, and RO feed systems where fluid quality is controlled.

Issues occur when they are pushed into process duties involving temperature variation, suspended solids, or frequent flow changes. Seal life and internal wear become limiting factors. These pumps deliver efficiency only when operating close to their design point.

Vertical Inline Pumps – HVAC and Circulation-Focused Designs

Vertical inline pumps are popular in HVAC systems because they simplify piping and reduce floor space requirements. Their biggest advantage is installation flexibility in mechanical rooms with limited space.

However, they are often misapplied in applications requiring variable suction conditions or where system cleanliness is poor. Inline designs rely heavily on proper alignment and clean fluids. When used correctly in chilled water and hot water circulation, they offer predictable performance and easy maintenance access.

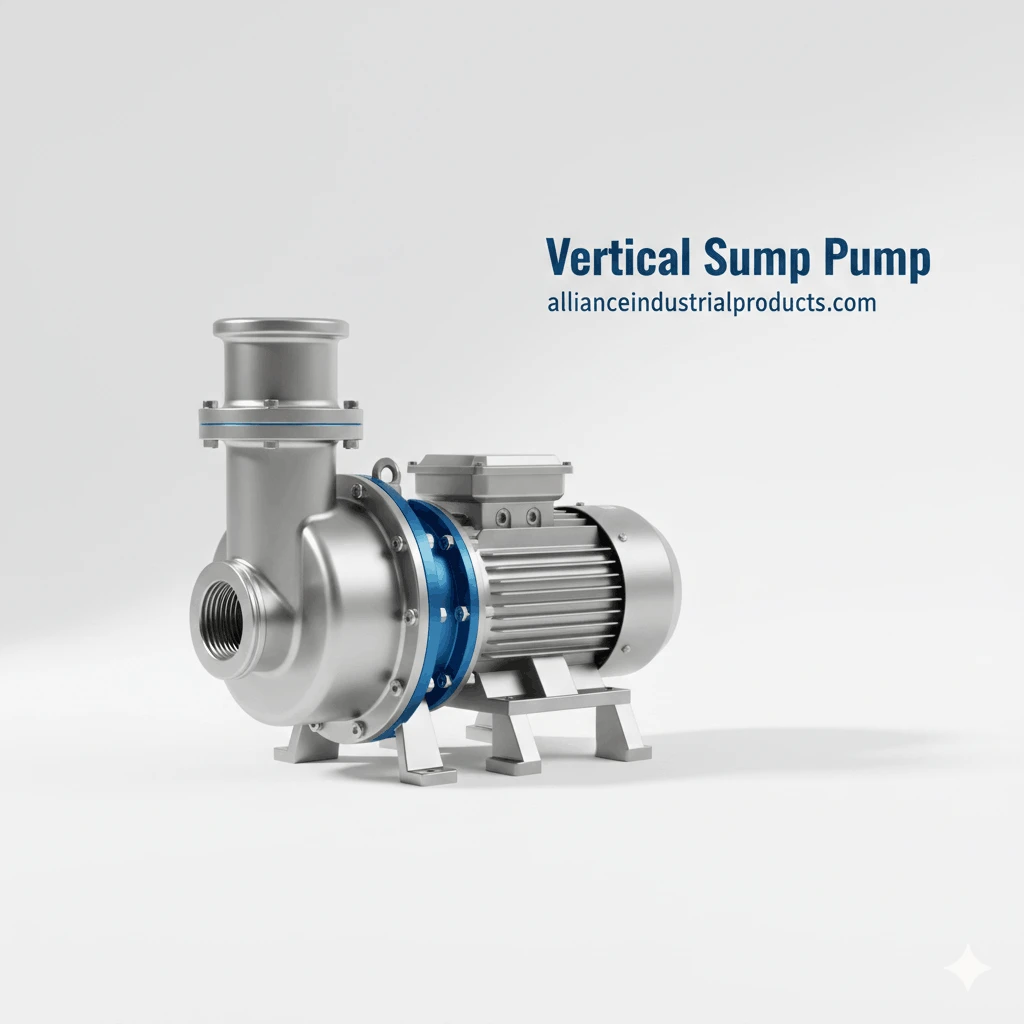

Vertical Sump Pumps – Handling Contaminated and Abrasive Fluids

Vertical sump pumps are designed for situations where no positive suction head is available, such as pits, sumps, and trenches. They are commonly used in chemical plants, mining operations, and wastewater facilities.

The biggest selection error here is underestimating solids content or chemical compatibility. Shaft length, bearing arrangement, and material selection determine whether the pump runs reliably or becomes a frequent maintenance issue. These pumps are built for abuse, but only when specified correctly.

Vertical Cantilever Pumps – When Seals Are a Liability

Vertical cantilever pumps are preferred in corrosive, high-temperature, or slurry applications where mechanical seals create more problems than they solve. With no submerged bearings and minimal wetted components, they reduce failure points in harsh environments.

They are not general-purpose pumps. Their strength lies in niche applications where fluid leakage, seal flushing, or contamination risks must be minimized. Selecting the wrong metallurgy or overextending shaft length can quickly negate their advantages.

Common Vertical Pump Selection Mistakes Seen on Site

Many vertical pump failures are not design flaws but selection errors. Pumps are chosen based on catalogue data rather than site conditions, leading to avoidable downtime.

Common issues include ignoring NPSH margins, assuming all vertical pumps handle solids equally, and overlooking maintenance access during layout planning. These mistakes usually surface after commissioning, when correction becomes expensive.

Why Choose Alliance Industrial Products

Alliance Industrial Products works with engineers and project teams before equipment is finalized, not after problems appear. The focus is on application understanding, not pushing a standard model.

With a wide portfolio of vertical pumps, motors, valves, and control panels, the team supports proper selection based on duty conditions, lifecycle cost, and maintenance strategy. This reduces operational risk and improves long-term plant reliability.

For technical discussions, pump selection validation, or quotation support, Alliance Industrial Products offers practical, experience-driven consultation rather than generic recommendations.

FAQs

The decision depends on suction conditions and fluid source. Vertical turbine pumps require controlled submergence and cleaner fluids, while vertical sump pumps are built for open pits and contaminated liquids

Only in controlled conditions. They perform best with clean fluids and steady operation. For variable or abrasive processes, other vertical designs are more reliable long term.

Improper bearing lubrication and incorrect shaft alignment are the most common causes of failure. Both are usually linked to poor initial selection and installation planning.

Not always. They work well where space is limited and fluids are clean, but system layout and suction conditions must be evaluated before replacement.